One of the most important things, particularly in the current climate is ensuring that our processes are hygienic and traceable from source of product to client. Our Spring Water is bottled in Leicestershire and is invariably delivered within 48 hours of bottling. we use our own locally based staff for deliveries and sanitisations.

Our water cooler sanitisation process is absolutely second to none, we are rigorous in our method; you can be assured of the best, most hygienic servicing at all times to comply with the WHA (Water Dispenser and Hydration Association) standards.

Our water cooler Sanitisation Process

Before the water cooler can be dismantled, the water bottle has to be removed and the water drained. The water trail components are then removed and bagged.

The water cooler casing is then descaled and disinfected. The removed components are then replaced with pre-sanitised parts.

The original water bottle is placed back on top of the water cooler and up to 2 litres of water will be flushed through. This will ensure everything is working as it should; without leaks or cleaning residue.

All removed parts are then taken back to our sanitisation room to under go a rigorous cleaning process of descaling, sterilisation, rinsing and drying.

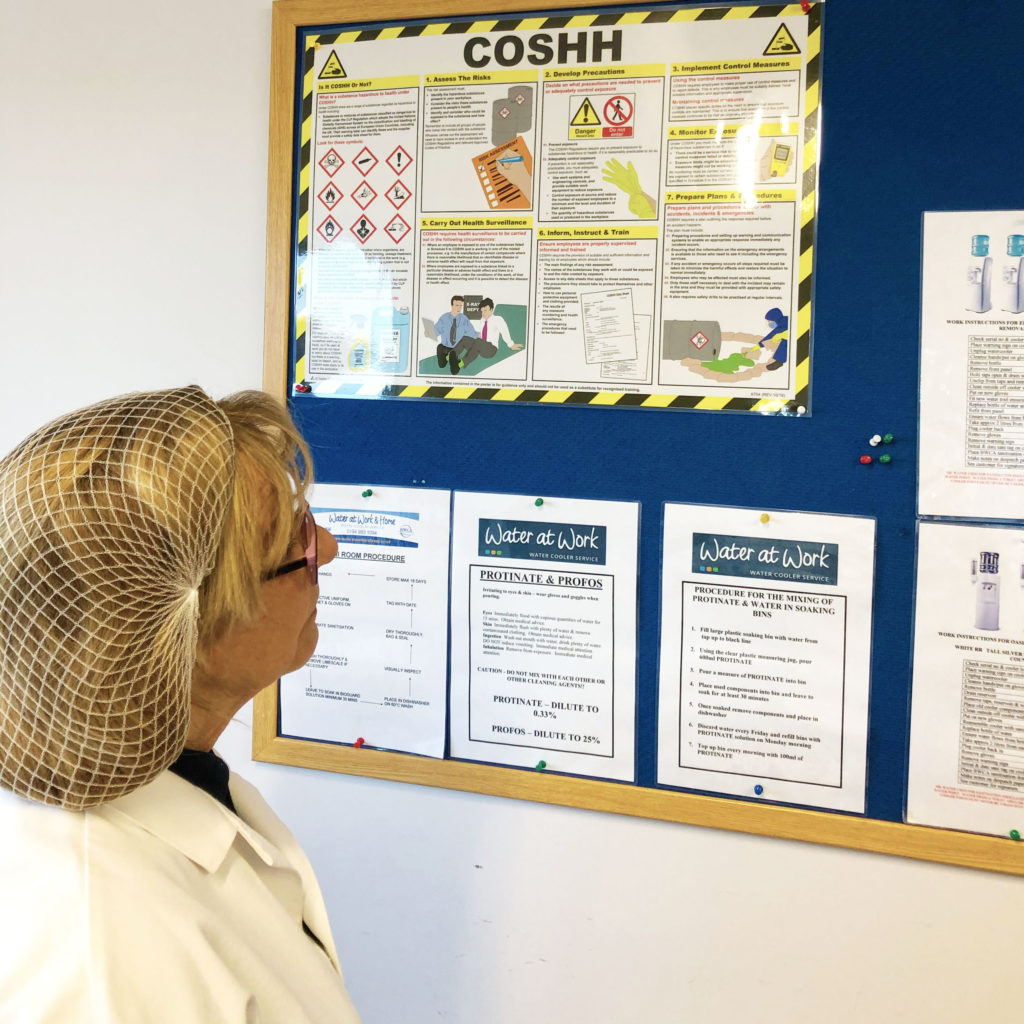

Our sanitisation room has strict rules in place which we must comply with; lab coats, hairnets and gloves must be worn at all times and no food or drink can be consumed within its walls.

Why we sanitise our water coolers

By now you know what our sanitisation process is, but why do we do it?

As spring water doesn’t contain any chemicals the development of bacterial matter and biofilm within water coolers is inevitable through human interaction.

A regular sanitisation programme is so important as after 3-4 months bacterial biofilm will start to form within your water cooler. If left unsanitised this can cause biofilm and colonies, leading to bad tasting water and eventually illness.

The Cleaning

agents we use.

Protinate is used for the regular cleaning and sanitising of our water coolers. It keeps the water trails clean from proteins, it’s taint free and eliminates biofilm deposits and colonies.

Profos is an acidic descaler used to rapidly remove limescale build up from the water trail.

Selden C003 Cleaner is a multi purpose Bactericidal Cleaner. It has powerful degreasing agents and is proven to kill MRSA and E.coli. It’s non-tainting and food safe, it does not require rinsing.